How Solenoid Valves Control Fluid and Gas Flow

Imagine trying to direct rush hour traffic without any traffic lights. Chaos, right? That’s what fluid and gas systems would look like without solenoid valves. These unsung heroes silently manage the flow of everything from your morning coffee machine to massive industrial pipelines. Whether you’re an engineer or just curious about how things work, understanding these valves unlocks a fascinating world of electromechanical control. Let’s dive into how solenoid valves control fluid and gas flow.

Introduction to Solenoid Valves

A solenoid valve uses an electric current to generate a magnetic field, which, in turn, moves a mechanism that regulates the opening of fluid or gas flow. You will find them everywhere, from household appliances to complex aerospace systems, acting as the critical switch that starts or stops the movement of media.

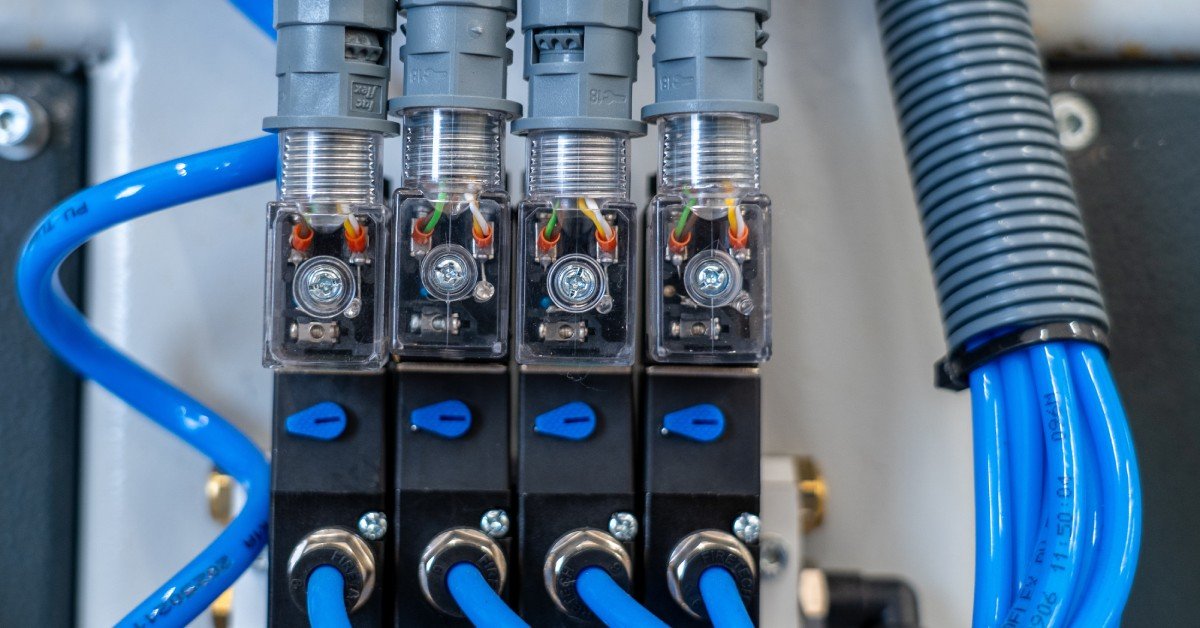

Basic Components of a Solenoid Valve

The valve consists of two main parts: the solenoid and the valve body. The solenoid houses a coil of wire and a movable plunger (or armature). The valve body contains the orifice through which the fluid or gas flows. When you energize the coil, it creates a magnetic field that pulls the plunger, opening or closing the orifice.

How Solenoid Valves Work

The process begins when an electrical current passes through the coil. This current generates a magnetic field. The magnetic strength pulls the plunger up or pushes it down, depending on the design. This movement changes the state of the valve, allowing liquid or gas to pass through or blocking it completely. When the current stops, a spring typically returns the plunger to the original position.

Types of Solenoid Valves

Direct-acting valves use the plunger directly to open or close the main orifice. These work well in low-flow situations. Pilot-operated valves, however, use pressure to help the valve open. The solenoid commands a smaller pilot port, altering the pressure balance and allowing the main valve to open. This design suits high-pressure and high-flow applications.

Common Applications of Solenoid Valves

You encounter these valves more often than you think. They control the water flow in your washing machine and dishwasher. In the medical field, they manage oxygen delivery in respiratory equipment. Industrial plants use them to mix chemicals precisely or control pneumatic machinery.

Selecting the Right Solenoid

Choosing the correct valve requires knowing your media. Is it a corrosive chemical, a gas, or simple water? You must also consider the required pressure, temperature, and flow rate. Understanding the specific solenoid valve flow paths is crucial, as different designs route fluid through the valve body differently.

Solenoid valves control fluid and gas flow and combine innovation with reliability to meet the demands of today’s advanced technologies. Whether you’re optimizing an industrial process or enhancing a household appliance, their precision and adaptability make them indispensable. By choosing the right solenoid valve for your needs, you can ensure optimal performance, safety, and efficiency in your operations. Don’t wait—unlock the potential of cutting-edge valve technology and take your systems to the next level!