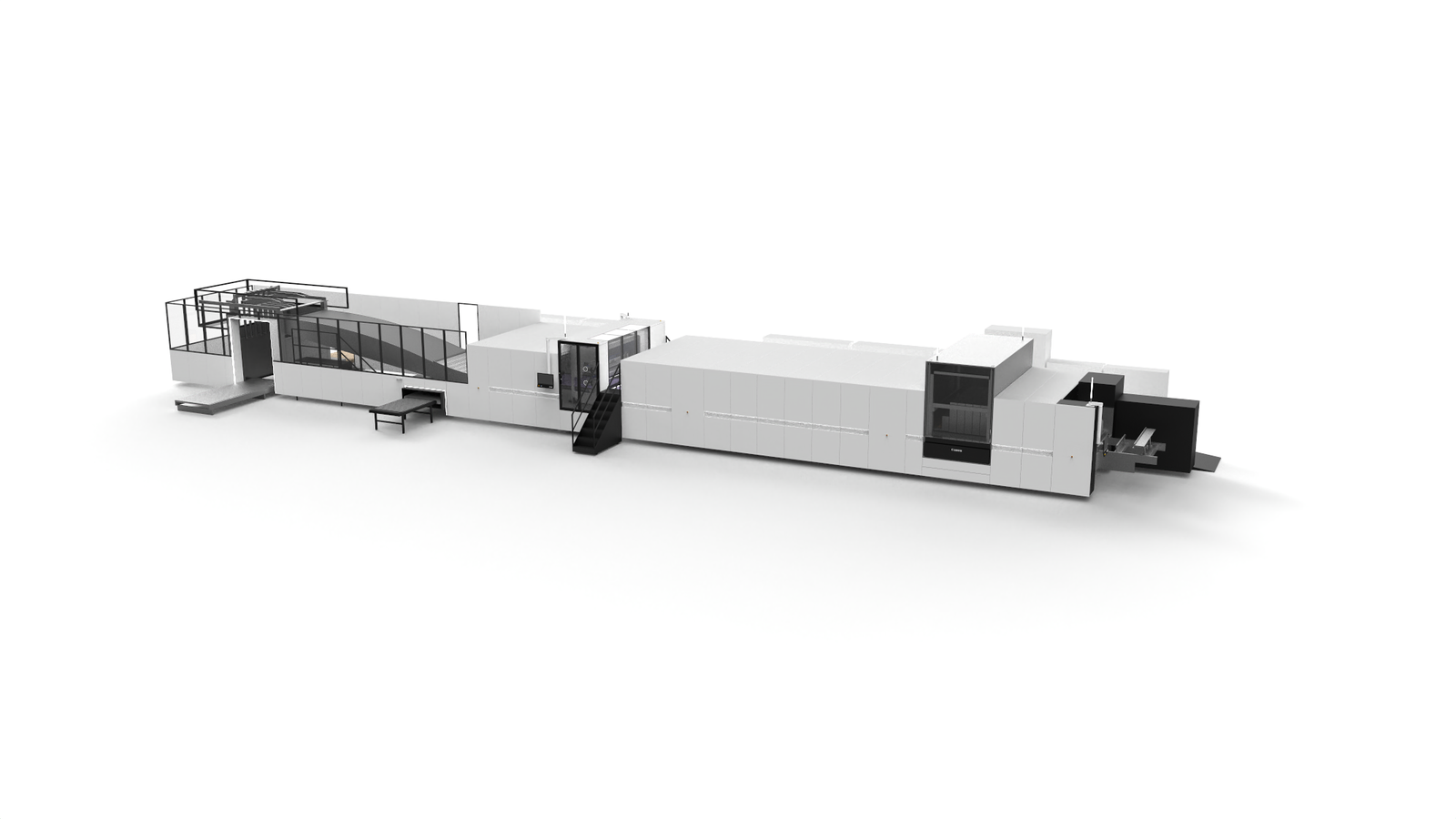

Canon unveils corrPRESS iB17 for high-speed digital corrugated packaging

Canon has unveiled the corrPRESS iB17, a next-generation inkjet press that redefines digital corrugated packaging production. The new press was introduced during the FEFCO Technical Seminar 2025 in Rome. It delivers industrial-scale productivity and offset-like quality at speeds of up to 8,000 square meters per hour.

The corrPRESS iB17 prints directly on corrugated boards up to 1.7 meters wide. It uses water-based inks and a primer safe for indirect food contact. The system combines automation and digital flexibility for short- to medium-length runs while reducing operator requirements and turnaround time.

Designed for industrial productivity

Canon built the corrPRESS iB17 to meet the growing demand for shorter print runs and faster delivery. It enables cost-efficient production of up to 20,000 square meters per run, extending digital printing beyond traditional limits.

Automated printhead cleaning and quality control reduce manual intervention and downtime. The system also eliminates printing plates, chemicals, and wastewater, supporting cleaner and more efficient production.

The technology improves sustainability by printing only what is needed. It ensures lower waste, better energy use, and faster adjustments to changing production needs.

Delivering offset-quality performance

The corrPRESS iB17 features Canon’s 1200 dpi piezo printheads and water-based pigment inks. This setup produces sharp details, vibrant colors, and consistent results across coated and uncoated boards.

A spot primer system enhances ink adhesion and color accuracy on all corrugated materials. Canon’s optimized drying technology also reduces board stress and energy use without compromising print quality.

The system supports boards between 1 mm and 8 mm thick, covering most retail packaging applications. With Canon controlling all key components—printheads, inks, and drying—it ensures full integration, reliability, and precision.

“Corrugated converters face rising demands for shorter runs, more variants, and faster turnaround without compromising quality or cost,” said Jennifer Kolloczek, Senior Director of Marketing & Innovation, Production Printing, Canon EMEA. “The corrPRESS iB17 empowers converters to respond with agility and unlock new growth opportunities.”