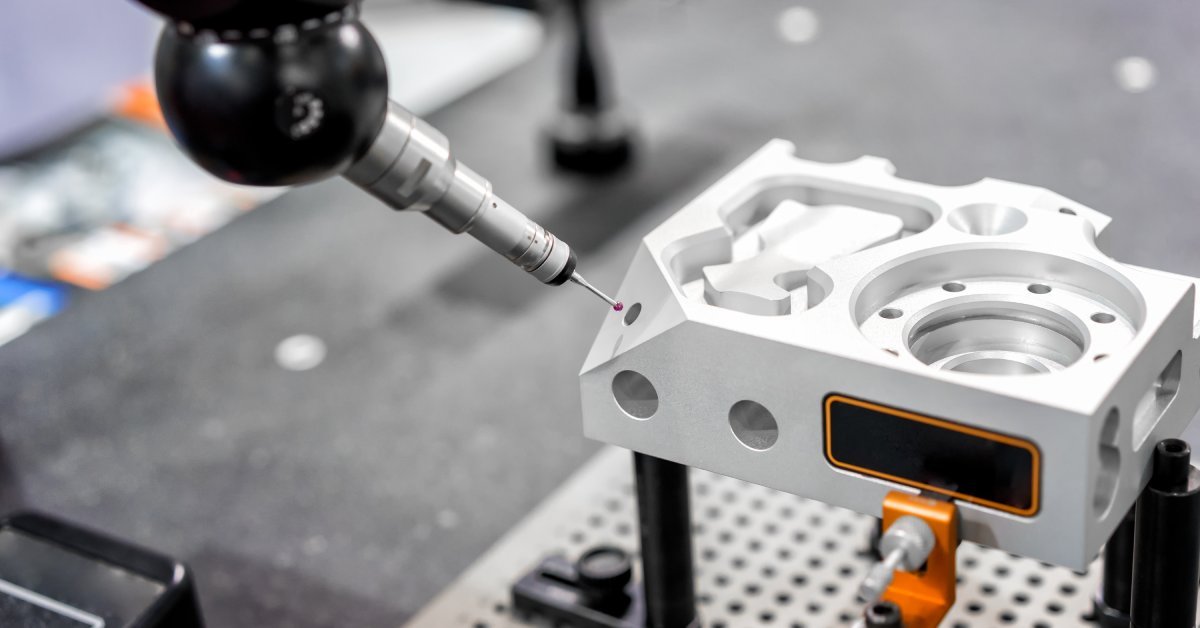

Why Measuring Machines Need Such Frequent Calibrations

Precision is the backbone of the manufacturing and quality control industries. Measuring machines play a vital role in ensuring accuracy, but their reliability hinges on frequent calibrations. The importance of frequent measuring machine calibrations is difficult to overstate, as even minor deviations can lead to major discrepancies in results. Below, we explore why maintaining calibration frequency is so vital for a business’s success.

Environmental Factors Impact Accuracy

Measuring machines operate in environments that can fluctuate in temperature, humidity, and vibration levels. These environmental changes can subtly affect machine performance over time. For example, slight temperature increases may cause materials in the machine to expand, altering measurements. Regular calibrations help account for these external influences, ensuring the machine consistently performs within accepted tolerances.

Wear and Tear on Mechanical Components

Daily use puts stress on a machine’s moving parts, which can degrade over time. Even the most durable materials experience wear under repetitive use. Components such as probes or guideways may not align as precisely as they once did due to this wear. Without calibration, these small shifts can build up, leading to cumulative errors. Staying on top of calibration schedules keeps the machine operating as designed, preserving its ability to deliver correct results.

Variation in Measurement Methods

Contact and non-contact CMM measurement methods differ greatly, both in their applications and their calibration demands. While you may think that contact CMMs require more frequent calibrations due to extra wear and tear, the truth is that calibration necessity is more about frequency of use. Regular, tailored calibration strategies are critical to accommodate both distinct methodologies and ensure accurate outputs regardless of the approach used.

Regulatory and Quality Requirements

Industries operating under strict quality standards rely on calibrated measuring machines to meet compliance goals. Audits and certifications often demand proof that teams conduct inspections using accurate, well-maintained equipment. A lapse in calibration could jeopardize certifications or lead to non-compliant products. By calibrating frequently, organizations demonstrate their commitment to quality, reducing risks of regulatory setbacks.

Calibrate Often and Deliver Accuracy

Ensuring precision starts with recognizing the importance of frequent measuring machine calibrations. Without routine adjustments, factors such as environmental changes, mechanical wear, and method-specific challenges can compromise machine performance. Regular calibration not only preserves accuracy but also ensures compliance with industry standards. Investing in proper maintenance ultimately safeguards product quality and operational efficiency.