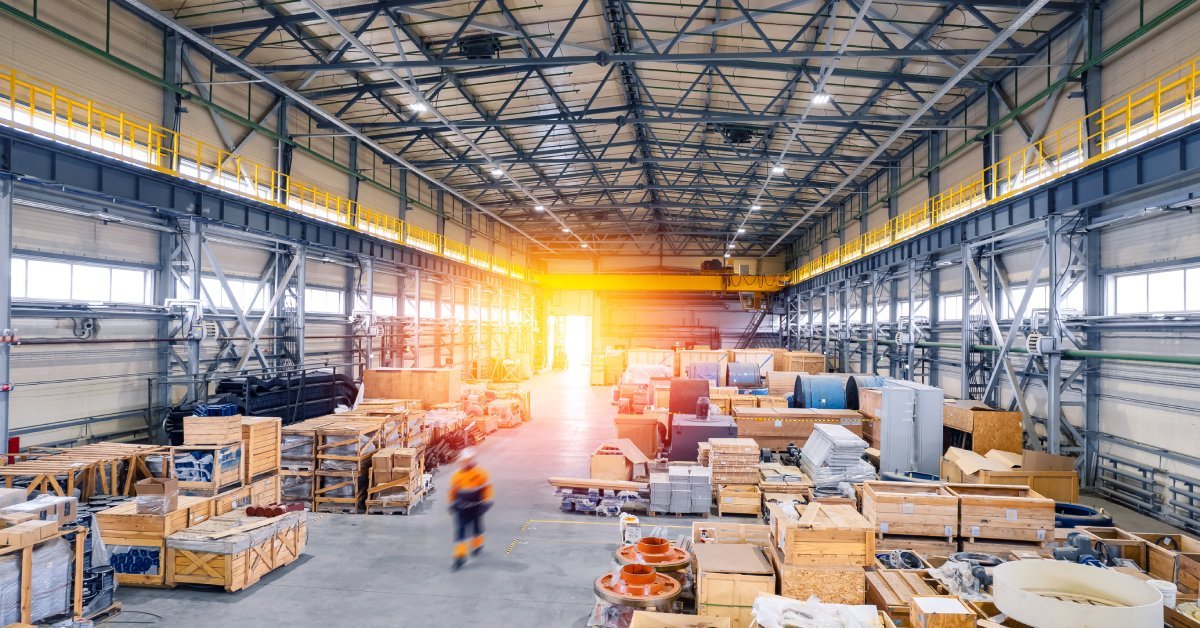

4 Steps To Boost Workshop Efficiency With the Right Tools

Workshop efficiency depends heavily on selecting appropriate equipment for your metalworking operations. The right machinery transforms time-consuming manual processes into streamlined production workflows.

Following these four steps to boost workshop efficiency with the right tools creates measurable improvements in output quality and operational speed.

Evaluate Your Current Equipment Needs

Start by evaluating your workshop’s daily operations to pinpoint bottlenecks and inefficiencies. Note tasks that take too much time or yield inconsistent results; this identifies areas where new equipment can make an immediate impact.

Also, consider the materials you frequently work with, as different materials require specific equipment capabilities for optimal performance. Pay close attention to:

- Track time spent on repetitive tasks

- Note quality issues with current processes

- Identify space constraints affecting workflow

Choose Precision Threading Equipment

Threading operations require accuracy and consistency. Vertical tapping machines enhance a shop’s capabilities by precisely creating internal threads. They eliminate human error and accelerate production compared to manual methods.

The vertical design saves valuable floor space while maintaining stability during operation. This configuration works particularly well for shops handling varied threading requirements across different materials.

Prioritize Workflow Optimization Tools

Select equipment that integrates seamlessly with existing processes. Machines requiring extensive setup changes disrupt production flow and reduce overall efficiency. Focus on tools that complement current workflows rather than forcing operational restructuring.

Consider equipment versatility when making selections. Multi-function machines handle diverse tasks without requiring multiple specialized tools, maximizing workspace utilization.

Implement Strategic Equipment Placement

Position new machinery to minimize material handling between operations. Strategic placement reduces movement time and creates smoother production flows. Group related processes together to minimize workflow interruptions.

Account for power requirements, ventilation needs, and maintenance access when planning equipment locations to ensure optimal functionality and efficiency. Proper planning prevents future operational constraints.

Following these strategic approaches to boost workshop efficiency with the right tools delivers measurable improvements in production capacity and output quality.

Equipment selection impacts every aspect of workshop operations, from daily productivity to long-term profitability. The right tools transform workshop capabilities while positioning your operation for sustained growth and success.