The Biofactory unveils new ‘Plug and Play’ system capable of instantly isolating healthcare facilities

The Biofactory, a Singapore-based biomedical technology manufacturer, unveiled a new portable “plug and play” system to isolate positively pressured healthcare facilities (Operating Theatres, Procedure Rooms and Intensive Care Units) and normal pressured facilities (Wards, Clinics, and Laboratories), in just an hour. The System of Portable AnteRoom for Containment, or SPARCX (SG-SPARC), is a breakthrough patented technology co-developed with the Department of Anaesthesiology, Singapore General Hospital (SGH) to better protect healthcare workers, patients and visitors.

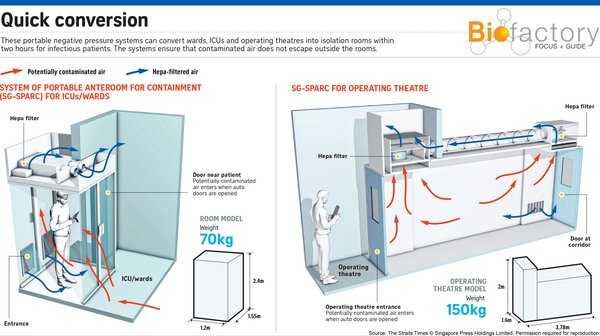

SPARCX (SG-SPARC) system is installed within the only entrance to the room and features advanced patented technology: a novel air decontamination protocol enabled by a powerful medical grade air filtration unit capable of up to 350 air exchanges per hour, continuous negative pressure and intelligently integrated airtight doors. These features allow it to isolate most rooms from the corridor regardless of the room’s internal pressure – positive (typically hardest to isolate), normal or negative: thereby preventing transmission of airborne diseases despite room-to-room movement and allow rapid conversion of existing infrastructure to meet sudden surges of infectious patients.

“We had seen how hospitals overseas struggled when they ran out of negative pressure isolation rooms during the COVID-19 pandemic. With SG-SPARC (SPARCX), we save time and money by avoiding the need to build temporary or new permanent structures, while protecting healthcare workers from any infected risks,” said Dr Mavis Teo, Consultant, Department of Anaesthesiology, SGH, who is a co-investigator of the project.

Installation is simple and no renovation is required. To isolate a room, the telescopic SPARCX (SG-SPARC) System is fitted within the entrance of the room and the edges are sealed off. It took one hour to set up the 70kg SPARCX (SG-SPARC) system at SGH’s Medical ICU, and one more will be added soon.

A larger model of SPARCX (SG-SPARC) System has also been developed and deployed to isolate the positively pressured operating theatre (OT). This model is able to fit an ICU bed, a ventilator and necessary equipment in order to enable healthcare workers to perform their jobs safely when handling any infected or suspected patients in the OT. The 150kg SPARCX (SG-SPARC) OT System measures 3.8m by 1.6m with a height of 2m, and only takes two hours to set up.

“With a special emphasis on rapid deployment, reliability and user-friendliness, installation is fuss-free and can be done quickly and simply– anywhere in the world. We have received strong interest from local and overseas buyers, and we are ready to meet the global demand for SPARCX Systems,” said Mr Gabriel Tan, Programme Director, The Biofactory.

To evaluate SPARCX (SG-SPARC) System’s virus containment efficacy, A*STAR’s Institute of Bioengineering & Nanotechnology (IBN) released live non-pathogenic viruses into a simulated patient room outfitted with the SPARCX (SG-SPARC) system. No viruses were found to have leaked from the patient room to the corridor.

“To our knowledge, this is the first time that such portable anteroom models were tested using live non-pathogenic viruses in Singapore. This method allows for more accurate testing compared to conventional methods, as it facilitates measurement of how many live virus particles are present,” said Professor Yang Yi Yan, Covering Executive Director, IBN, A*STAR.

The SPARCX (SG-SPARC) System is the result of an innovation research project funded by SingHealth Duke-NUS’s Urgent COVID-19 Research Fund.